High‑Precision six-sided-milling-process on a Vertical Milling Machine

- 邵萱 黃

- Oct 24, 2025

- 3 min read

Introduction:

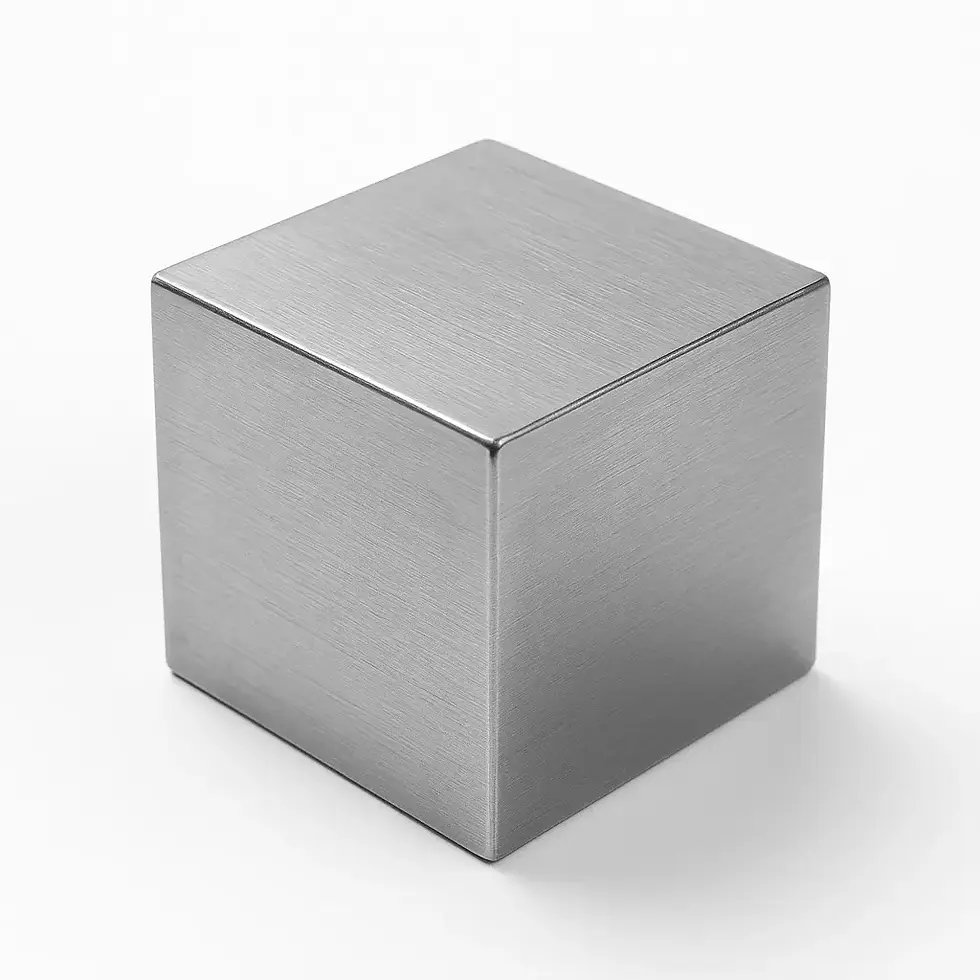

The six‑sided milling process is critical in mold manufacturing and mechanical part machining. Almost all components require six accurate reference surfaces. The perpendicularity and parallelism between these planes directly affect assembly accuracy, part fitment, and overall product performance. The six‑sided milling process establishes geometric accuracy through sequential machining of all six faces of a workpiece. Even without a five‑axis machine, a traditional vertical milling machine can achieve high precision when proper procedures and experience are applied.

1. Principle of six-sided-milling-process

“Six‑sided machining” means machining the six principal faces of a workpiece in sequence. After each face is machined, a new machining datum is established. This datum is then used to locate the next face, continuing until all six faces are machined. Final accuracy targets include: all six faces perpendicular to each other, and dimensional tolerance between faces controlled within ±0.01 mm—providing an accurate reference for subsequent CNC machining and part assembly.

2. Workflow Sequence for Six‑Sided Milling (Using a Vertical Milling Machine)

Before machining starts, the machine head angle must be aligned so the spindle is perpendicular to the table. After every face is milled, deburring should be done to prevent burrs from affecting positioning and precision.

A typical sequence is:

1️⃣Face 1 (Datum Surface): Clamp the blank in a vice, choose the largest face as the datum surface, and machine it.

Requirement: flat surface, surface roughness meets design standard.

2️⃣ Face 2: Use Face 1 as the reference in the vice.

Add a round bar support on the opposite side.

Mill the second face to establish a perpendicular relationship to Face 1.

A square or angle gauge can be used to verify 90° perpendicularity.

3️⃣ Face 3: Keep Face 1 against the vice fixed surface, then machine the surface opposite Face 2 (the third face).

Ensure full contact of Face 2 at the bottom to maintain perpendicular precision.

4️⃣ Face 4: Use Face 1 as the base datum, machine Face 4.

Guarantee parallelism with Face 2 and avoid dimensional deviation.

5️⃣ Face 5: Position Face 5 upward, use an angle gauge or dial indicator to check perpendicularity, then machine.

The vice angle may be adjusted as required to ensure consistency between top and bottom surfaces.

6️⃣ Face 6: Place Face 5 on the vice bottom surface, then machine the final face. After completion, use a caliper, angle gauge or 3‑D coordinate measuring machine to inspect perpendicularity and parallelism.

3. Key Process Tips & Techniques

Smart sequence planning: Choose the largest, most stable face for the datum. Follow the rule “first datum, then dimension; rough‑then‑finish”.

Clamping & fixture positioning: Use angle squares and parallel blocks for assistive positioning. Control clamping force to avoid distortion or slippage.

Tooling selection: For roughing use flat‑bottom end mills; for finishing use end mills or vertical milling cutters. Typical spindle speed: 1000–1500 rpm; feed rate according to material.

Precision control: After machining each face, immediately verify dimensions and perpendicularity. Using angle gauges or coordinate measuring machines is recommended.

4. Common Issues & Solutions

Issue | Possible Cause | Solution |

Surface not flat | Tool wear, inconsistent feed | Replace cutter, reduce feed rate |

Faces not perpendicular | Clamping angle error | Check datum verticality, reposition |

Excessive size deviation | Uneven clamping, work‑piece slip | Use locating pins, increase stability |

Surface roughness high | Cutter vibration, insufficient coolant | Increase tool rigidity, improve coolant supply |

5. Applications of Six‑Sided Milling

Six‑sided milling is one of the basic operations in mold and mechanical manufacturing. Common uses include:

Mold base and casting trimming

Mold slider & guide component machining

Machined parts & jig base production

Establishing reference flats on block‑shaped workpieces

At Howmin Co., Ltd., beyond traditional vertical milling, we also integrate three‑axis, five‑axis and deep‑hole drilling/milling equipment. We assist clients with one‑stop manufacturing—from rough blanks to precision components.

6. Conclusion: Vertical Milling Machines Can Achieve High‑Precision Six‑Sided Machining

While five‑axis CNC machining has become increasingly mature, as long as fixtures are properly designed and datum and sequence are strictly controlled, even a traditional vertical milling machine can reach high‑precision six‑sided machining standards. Six‑sided milling is not only a machining foundation—it is the core of mold precision. Through disciplined processes and years of experience, the mold quality can be significantly enhanced, while development cycles are shortened.

📌 Want to learn more about mold and component machining technologies?

👉 Contact Howmin Co., Ltd. and let our 30 + years of expertise deliver the most accurate and efficient machining solutions for you.。